WELDING WITH ALUMINUM |

|

Welding with aluminum is more difficult than with stainless or nickel. As it is written in the Principle page, aluminum easily conducts electricity. Thus, although the electric current flows, not much heat is produced and in addition, the heat escapes easily-making it hard to do spot welding.

However, a think plate around 100 micron (0.1 mm) is able to be welded with HSW-02A.

About welding capability, please click HERE. |

Welding of a thin plate of aluminum needs the release of a large amount of electric power in a short time and also the heat release so that the aluminum material will not break down.

In the photo above, a stick electrode is the way to tackle the heat release problem. Also, for the tip of the welding pen, it would better if the tip is a bit round rather than sharp.

In addition, adequate plunge pressure needs to be applied while the welding is on the process. |

If welding pinset is used, the heat released will not be enough, making a hole which causes the welding to be unstable. |

| |

For details about aluminum foil which is able to be welded by Yokodai.JP HSW-02A, please click HERE. |

WELDING WITH PHOSPATE BRONZE |

|

Phospate bronze (C5191) is a metal alloy of bronze, tin, and phosphate. It is strong against tension, and it is frequently used as an electrode's spring material Lead is sometimes added to the alloy, but the percentage is so small that there will not be a problem with RoHS.

Since it has almost the same conductivity rate and heat transfer rate with nickel, the spot welding process is also almost the same as nickel.

About welding capability, please click HERE. |

|

List of Conductivity Rate and Heat Transfer Rate of Metals (under room temperature) |

Metal Name |

Conductivity Rate |

Heat Trans. Rate

W/(m K) |

gold |

45.5 |

320 |

silver |

61.4 |

420 |

copper |

59.0 |

390 |

aluminum |

37.4 |

236 |

phosphate bronze |

13-15 |

133 |

nickel |

14.5 |

113 |

stainless steel |

6-9 |

15-25 |

iron |

9.9 |

84 |

|

| |

For strength evaluation result, please click HERE. |

WELDING WITH STEEL (SS/SK) BLOCKS AND DIFFERENT KIND OF METALS |

|

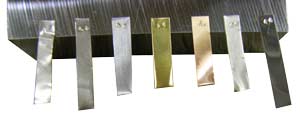

(UPPER PICTURE) SS50C Steel Block (16x60x60mm)

(FROM LEFT) inside () is thickness in mm

nickel (0.08)

nickel (0.15)

SS steel (0.2)

brass (0.2)

phosphate bronze (0.2)

nickel silver (0.2)

stainless steel (0.2)

(MIDDLE PICTURE) SS400 Steel Block (16x60x60mm)

nickel (0.08)

nickel (0.15)

SS steel (0.2)

brass (0.2)

nickel silver (0.2)

phosphate bronze (0.2)

stainless steel (0.2)

(LOWER PICTURE) SKD11Steel Block (16x60x60mm)

nickel (0.08)

nickel (0.15)

SS steel (0.2)

brass (0.2)

phosphate bronze (0.2)

nickel silver (0.2)

stainless steel (0.2)

|

| |

*) HSW-02A, HSW-EB1 (electrode) were used. |

|

SKD11 Steel Block and 0.45 mm Bronze line |

WELDING WITH STEEL (IRON) PLATE |

|

Steel plate is able to be welded in the same measure as stainless. Spot trace will appear really clear just as stainless welding using HSW-02A.

About welding capability, please click HERE. |

| |

For strength evaluation results, please click HERE. |