|

THERMOCOUPLE WELDING |

| About Thermocouple |

How To Make A Contact Point |

|

If two different kind of metal lines are connected and are heated in one connection point, electricity will flow. This is called Seebeck effect. Thermocouple uses this as a temperature sensor. |

|

[TWISTED LINE] It is just twisting the lines together, but in a certain semiconductor manufacturer, during experiment, it is used for IC's temperature measurement - which is possible using a thermocouple with line diameter more than 0.3 mm.

[WELDING] Using a specific welder, a ball shape-welded thermocouple is currently on the market.

*) According to the purpose of use, sometimes mechanical strength is needed; however, judging on how small is the influence of a measurement tool on a non-measurement one, it is better if thermocouple is welded simply using thin lines. Yokodai.JP is currently verifying that HSW-02A can weld a up to 0.3 - 0.25 mm thermocouple with naked eyes. |

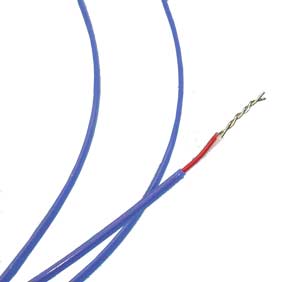

| Thermocouple uses different kinds of metal combinations for a certain range of temperature. The most used combinations are the ones called Chromel-Alumel which is also known as K-type (a kind of Nickel alloy), and Bronze-Constantan which is also known as T-type (constantan is an alloy of bronze and nickel). |

| |

|

ALUMEL-CHROMEL THERMOCOUPLE |

BRONZE-CONSTANTAN THERMOCOUPLE |

Chromel - Alumel 0.32 mm in diameter, twisted first

before welding (HSW-02A + HSW-PC1 + HSW-W2)

|

Enlarged picture of welding Bronze - Constantan Thermocouple with 0.32 mm in circular diameter

(

HSW-02A + HSW-PC1 + HSW-TC1) |

Welding Alumel - Chromel 0.1 mm and 0.025 mm

(Click the picture to enlarge) |

|

Points to consider on welding a thin 0.1mm are the cooling of contantan, the control of electric current and electrode's choice.

|

| This example used both stick electrode and the standard welding pen. |

|

Enlarged picture of welding Alumel 0.1 mm and 0.025 mm

Welded with naked eyes (TC Pinset was used)

|

Click To Enlarge

[ Machine Used ] HSW-01A �{ HSW-PC1 (power controller)

HSW-EB1 (stick electrode)

[ Tested Material ] Bronze - Contantan 0.1 mm (circular shape)

|

* Recommended Set For Thermocouple * |

HSW-01A Thermocouple Set

|

HSW-02A Thermocouple Set

HSW-02A Thermocouple Set

|

|

Using a TC Pinset (HSW-TC1) designed specifically for thermocouple use,

it is able to weld with 0.025 diameter thermocouple using naked eyes.

Adjustment of welding pressure would be needed, so please use it together with power controller (HSW-PC1).

This movie can be played using a standard Windows MediaPlayer.

|

HSW-02A thermocouple welding set can be adjusted in two phase, making it easier than HSW-01A thermocouple set. Also, when welding a thin thermocouple, HSW-02A thermocouple welding set is recommended. |

Thermocouple welding was done with naked eyes,

Thermocouple welding was done with naked eyes,

but to check the result and take pictures, microscope was used. |

|

| When welding a 0.025mm, 0.3mm looks really thick. |